Place of Origin:

Hangzhou, ChinaBrand Name:

LongoneWarranty:

12 Months

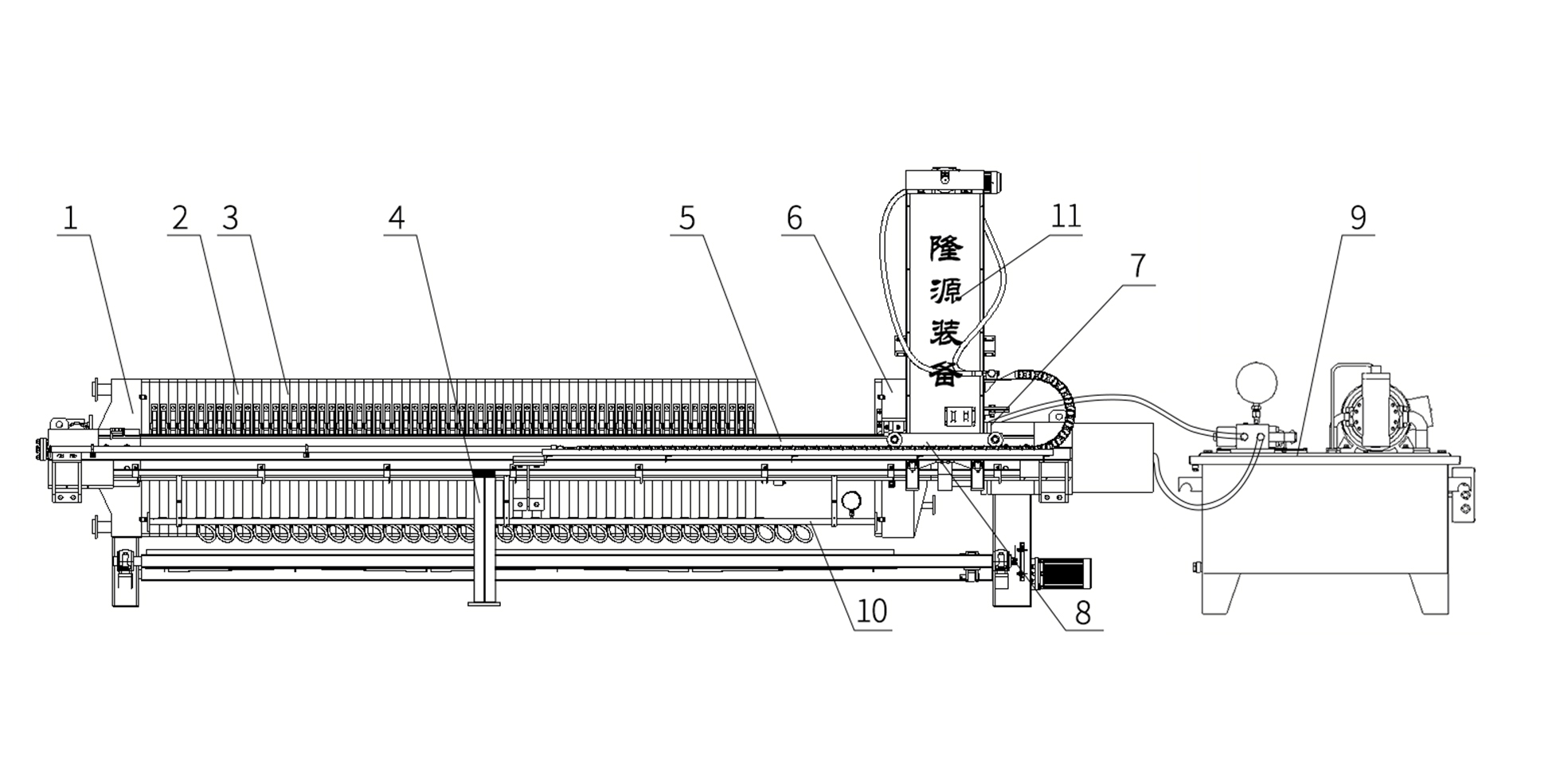

The chambe filter press is a technologically advanced separation machinery product that integrates machinery, electricity and hydraulics. lt consists of five parts: frame part, filter part (filter plate, membrane plate, filter cloth), pullingplate part, hydraulic part and electrical control part.

The frame part is the main body of the machine, used to support the filter mechanism and connect other components. lt is mainly composed ofthrust plate, pressing plate, cylinder block and main beam.

The filtration part is composed of filter plates aranged on the main beam in a certain order, filter cloth sandwichedbetween the filter plates, and membrane (membrane models have) filter plates. The filter plates and filter cloths (andmembrane filter plates) are arranged altemately to form several independent filter units - filter chambers.

The automatic pulling plate part consists of a variable frequency motor (hydraulic motor, manipulator,transmissionmechanism and pause dewice.

The hydraulic part is the power device that drives the pressing plate to press or loosen the filter plate. t is equippedwith a plunger pump and various control valves.

The electronic control part is the control center ofthe entire system.

Longone Chamber Filter press

1. Thrust Plate

2. Membrane Plates

3. Chamber Plates

4. Middle Support

5. Main Beam

6. Compression Plate

7. Hydraulic Cylinder

8. Automatic Shifting System

9. Hydraulic Station

10.Squeezing Tube

It is easy to operate and maintenance as the filter press is compressed by the hydraulic jack system and mechanical locking.

The maximum filtering (squeezing) pressure is 4.0 Mpa(40 Bar).

The filter press adopts the reinforced PP filter plates. The filter plate featured in high strength, light weight, anti-corrosive, acid and alkaline resistant, non-toxic and odorless is molding pressed with patent technology.

The frame of filter press is weld steel structure with stable mechanical performance, delicate type and attractive appearance.

The filter press can be configured with related auxiliary systems. It can be equipped with a mobile device, achieving automatic pulling of the board. It can be equipped with a filter cloth rapping device to completely remove the filter cake. It can be equipped with a filter cloth cleaning device, which automatically cleans the filter cloth and improves filtration efficiency. The choice of auxiliary system depends on the specific needs of the user.

The filter press is equipped with an electronic control system, achieving automatic control of operating procedures.

CE Qualification

ISO9001:2015 Quality Management System Certificate

ISO14001:2015 Environmental Management System Certificate

ISO45001:2018 Occupational Health and Safety Management System Certificate

Invention Patent

Pharmaceutical Industry

Antibiotics, calcium phytate, inositol, glycosylase, Chinese medicine, pharmaceutical intermediates.

Food Industry

Vegetable oil, monosodium glutamate, starch, cyclamate, yeast, vegetable protein, carrageenan, Xanthan gum, food additives.

Non-Metallic Mineral Industry

Kaolin, bentonite, activated clay, diatomite, mica, graphite, gypsum, fluorite, silica lime, quartz sand, phosphate ore, pyrite.

Smelting Industry

Nonferrous metals smelting (gold, silver, copper, zinc, nickel, cobalt, aluminum, calcium, tungsten, lithium), ferrous metals (iron, manganese), rare earth, clean coal, tail coal.

Chemical Industry

Petrochemical industry, Inorganic salt, Dyes, Titanium dioxide, White carbon black, Activated carbon, Chemical intermediates.

New Energy Industry

Iron phosphate, lithium iron phosphate, ternary precursor, battery recycling, photovoltaic cutting fluid, lithium carbonate, lepomica beneficiation.

Environmental Protection Industry

Municipal wastewater、River dredging sludge、Dinking water waste slidge、Sand washing wastewater、Steel wastewater、Paper making wastewater、Industrial wastewater.

Established back in 2007, Longone Equipment Inc. is a professional filtration system overall solutions provider.

As an automatic filter press manufacturer, we offer a wide range of filter presses with up-to-date technology suitable for both standard and heavy-duty performance levels. Our business including PP Recessed Plate (Polypropylene), PP Membrane Plate, CGR Plate, and sophisticated range of accessories for all cases.

Having developed great experience by working in various applications, which present some of the most difficult slurries to treat and require high pressure to obtain great results, Longone filter press will handle any slurry in any sector.

Under the support of up-to-date tooling equipment, which can produce high-difficulty and high-complexity filter press, Longone has become the first-class producer of China.

As a company, our concentration is not limited to designing and manufacturing but we also provide support related to the servicing and consultation for filtering. Right from suggesting the right kind of filter press to providing pilot trail press for filtration trials, our experienced team is always ready to serve you better. And our products are widely used in new energy, environmental protection, chemical, mineral smelting, non-metallic, pharmaceutical, food and other industries.

The working principle of a filter press involves several steps, that are part of a filtration cycle. Let’s explore each step in detail:

Filtration cycle

The filtration cycle of a filter press consists of four stages: filling, filtration, cake formation, and cake discharge.

Filling the filter chambers

In the first stage, the filter chambers are filled with slurry, a mixture of solid particles and liquid. Pumping the slurry into the filter press causes the liquid to flow through the filter media, leaving the particles behind.

Filtration and cake formation

Once the filter chambers are filled, pressure is applied using the hydraulic system. This pressure forces the liquid to pass through the filter cloths, while the solid particles accumulate on the filter plates, forming a cake.

Cake discharge

After the filtration stage, the filter press is ready for cake discharge. The cake is removed from the filter plates either manually or automatically, depending on the type of filter press.

Focus on our WeChat official account